The spiral blades are fixed with new L-shaped bricks and stainless steel wear-resistant screws, covering both the side and end faces of the steel blades to prevent material from coming into contact with the steel during the dehydration process, thereby improving performance and service life.

The scraper is made of high-strength wear-resistant hard alloy, which is less prone to detachment and fragmentation compared to aluminum oxide material, and has good wear resistance.

The sieve is made of 99 porcelain, and the spiral drum is partially protected with 95 porcelain, making the components less prone to wear.

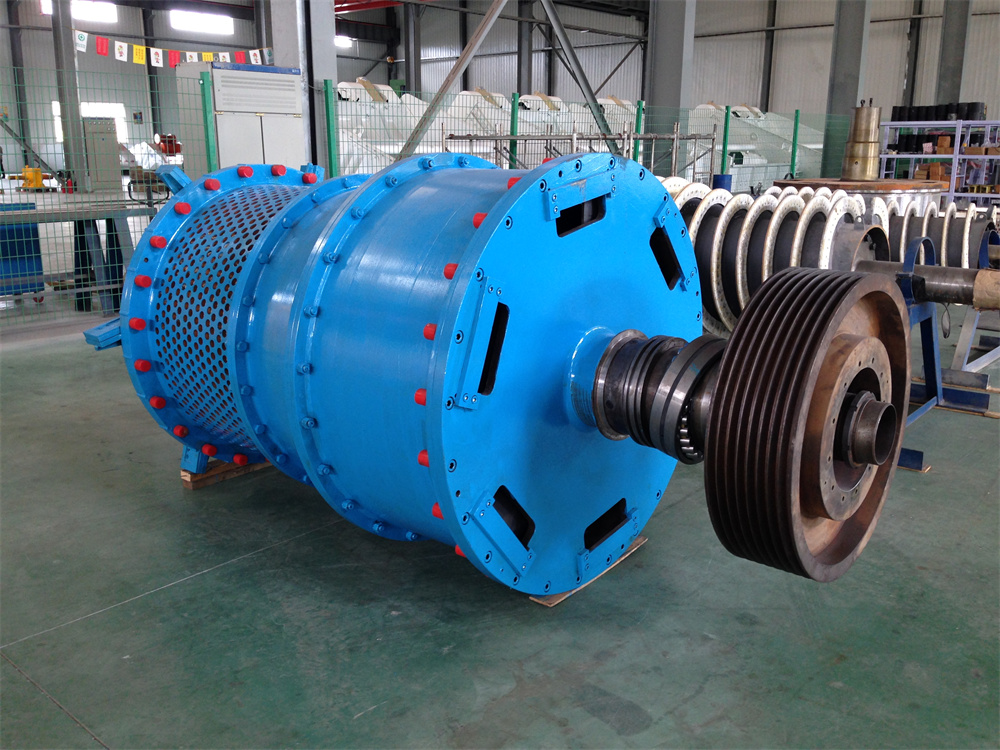

The overall transmission components are light, low energy consumption, low failure, and low cost.

The structure is advanced, with high transmission efficiency. The moisture content of the clean coal slurry product is 14-16%, and the moisture content of the tail coal slurry product is 16-18%.

Safe and reliable, compact structure, and easy maintenance.

Large processing capacity per unit volume and low investment;

High degree of automation: equipped with automatic adjustment of feeding function; Equipped with monitoring and protection devices for bearing temperature, system vibration, working torque, drive motor current, grounding, etc., to achieve automatic monitoring and control of all equipment, instruments, valves, etc; Equipped with safety protection devices such as oil circuit blockage protection, vibration protection, temperature monitoring and protection, comprehensive motor protector, feed adjustment, etc., the entire machine is protected through automatic alarm, forced shutdown, etc.